ミクロな機械が切り拓く次世代の医療とヘルスケア

東北大学 大学院医工学研究科 医工学専攻 生体機械システム医工学講座

ナノデバイス医工学研究分野

東北大学 大学院工学研究科 ロボティクス専攻

バイオメカニクス講座 ナノデバイス医工学分野

ResearchEnlish/Japanese

Development of minimally invasive medical devices with high precision and multi functions

Although, minimally invasive examinations and therapies with endoscopes and catheters are already widely performed without large incisions and physical burden on the patient, required smallness and particular shape restrict their functions and preciseness of the tools. For future of minimally invasive medicine, development of new fabrication technologies, high-performance multi-functionalized medical tools has been performed. We aim to realize semiautomated microrobots which perform precise diagnosis and therapy in the human body in future.

Poster PDF of intravital measurement devices

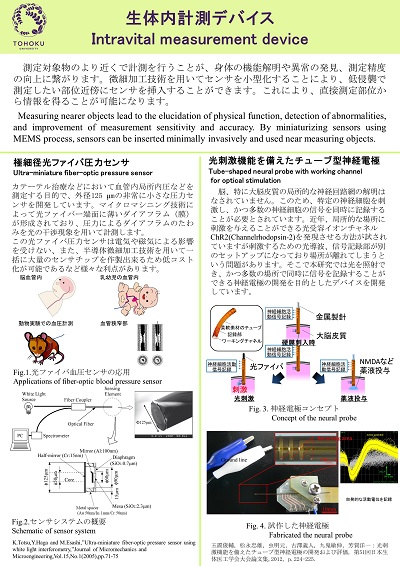

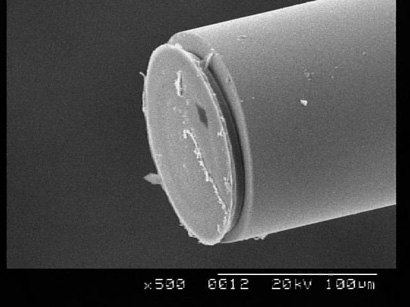

Fiber-Optic Pressure Sensor

Small diameter (125 um) fiber optic pressure sensor has been developed

for measuring locai internal pressure, for example, blood pressure in blood

vessel during catheterization. A thin diaphragm is formed at the end of

an optical fiber using MEMS technology and deformation of the diaphragm

by the pressure is detected interferometrically. This fiber optic sensor

is electrical hazard free and its signal is not affected by an electromagnetic

interference.

Small diameter (125 um) fiber optic pressure sensor has been developed

for measuring locai internal pressure, for example, blood pressure in blood

vessel during catheterization. A thin diaphragm is formed at the end of

an optical fiber using MEMS technology and deformation of the diaphragm

by the pressure is detected interferometrically. This fiber optic sensor

is electrical hazard free and its signal is not affected by an electromagnetic

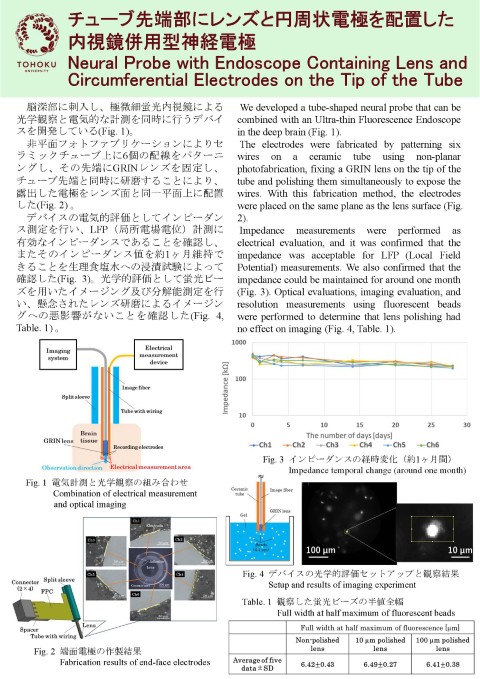

interference.Neural Probe with Endoscope Containing Lens and Circumferential Electrodes

on the Tip of the Tube

Poster PDF of neural probe with endoscope

Poster PDF of in vivo bending device

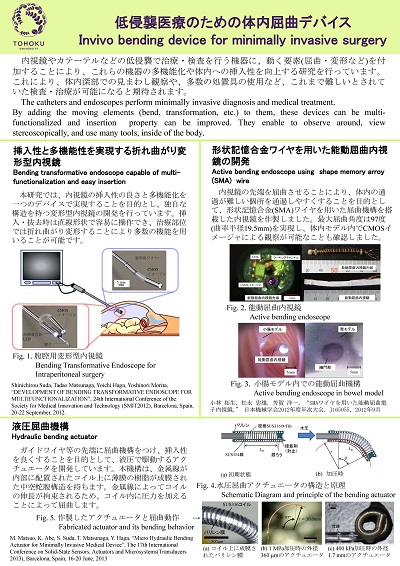

Active Catheter (SMA; Shape Memory Alloy type)

(Movie will be played by click)

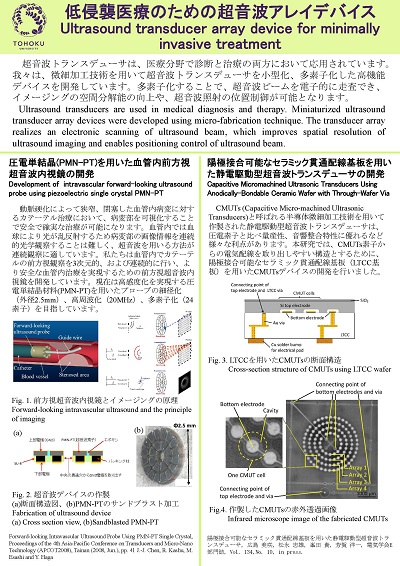

Poster PDF of ultrasound transducer array devices

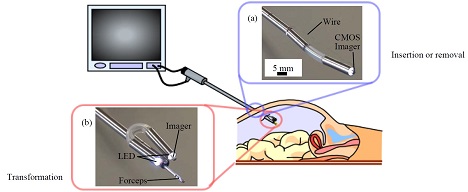

Transformable Folding Endoscope which Enable Minimally Insertion and Multifunctionalization

Transformative endoscope which have novel folding structre has been desinged. When the endoscope is inserted into or extracted out of the human body, its shape is straight for minimally insertion, and transformed in folding shape when the endoscope is in the cavity of the body by wire traction, and enable several functions. International patent has been obtained.

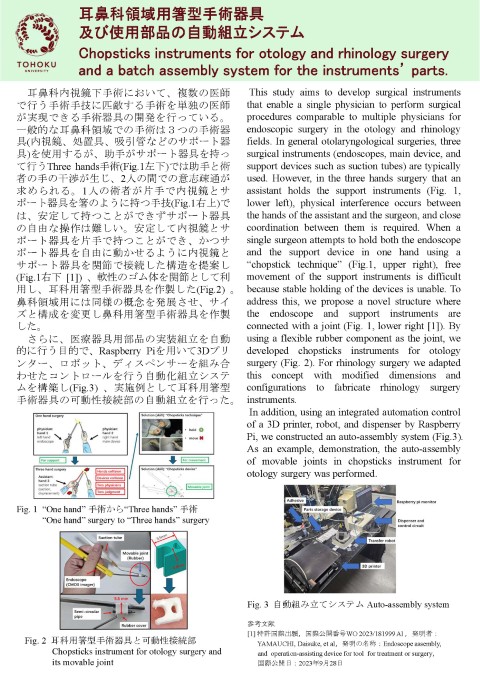

Chopsticks instruments for otology and rhinology surgery and a batch assembly

system for the instruments’ parts

Poster PDF of chopsticks instruments for otology and rhinology surgery and a batch assembly system for the instruments’ parts

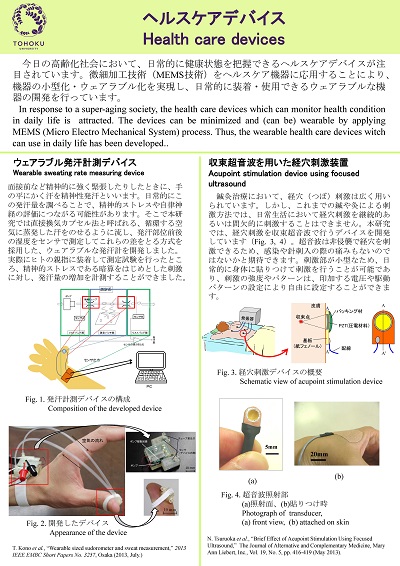

Development of unique health care devices which is located on the surface of the huaman body

Small ultrasonic sensor attached on the surface of the skin which measure blood pressure or hemodynamics noninvasively in daily life, and subepidermal interstitial fluid collection device which enable continuous monitoring of biological substances in blood without pain by utilizing needle patch for accupuncture have been developed. These devices are realized by using microfabrication technologies and provides high values which are useful for healthcare by internet connection.

Poster PDF of healthcare devices

Poster PDF of subepidermal microperfusion system

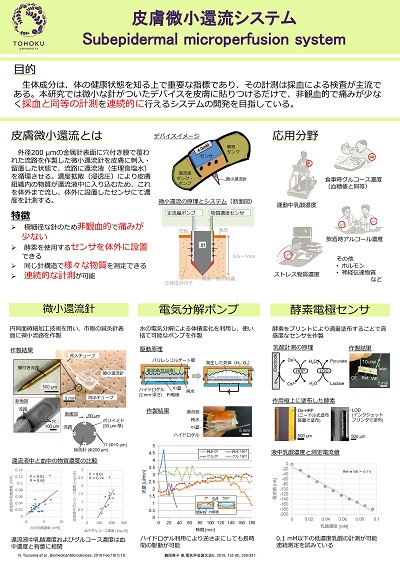

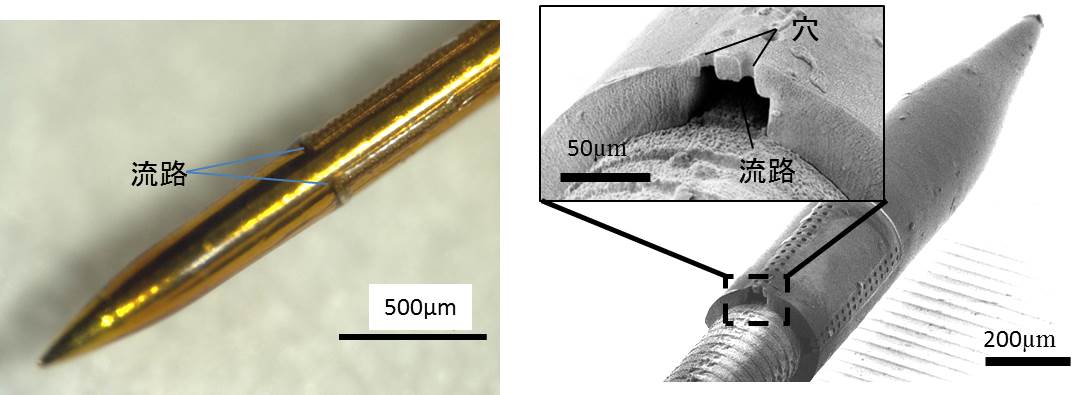

Microperfusion needle for measurement of subcutaneous bilogical substances

Daily monitoring of blood sugar or lactate in blood vessel facilitate management of health condition. Thin metal needle which is fabricated flow channel on the surface is shallowly inserted into the skin and biological substances are extracted and measured outside the body by performing microperfusion. Concentration of some low molecular weight substances in blood, for example, blood glucose or blood lactate are correlated to subepidermal glucose or lactate concentration and blood sampling become unnecessary. Flow channel with holes on the surface is fabricated on the surface of the needle of 0.2 mm diameter using non-planar microfabrication technologies.

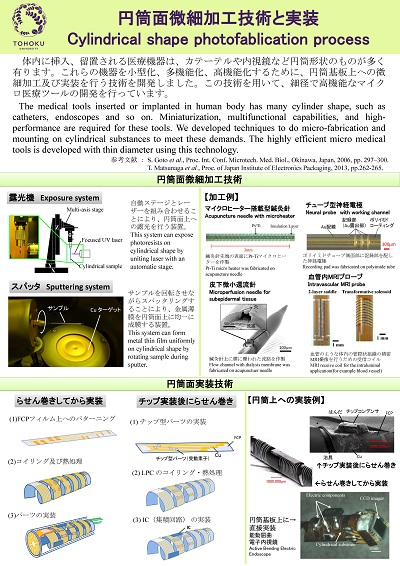

Development of non-planar photofabrication and non-planar assembly technologies

Semiconductor fabrication process and almost MEMS process with mass productivity utilize fabrication process on planar wafers. The processes are not suitable for assembly of medical devices for use in the human body and almost wearable healthcare devices. Development of new fabrication technologies and equipment for the technologies which perform microfabrication on the surface or on the inner surface of the tubes with a few diameters have been conducted. We aim widely used processes and devices by reducing production cost by process with good mass productivity.

Poster PDF of cylindrical shape photofabrication process

Development of organ model with microsensors for evaluation of surgical techniques and aid of development of medical devices

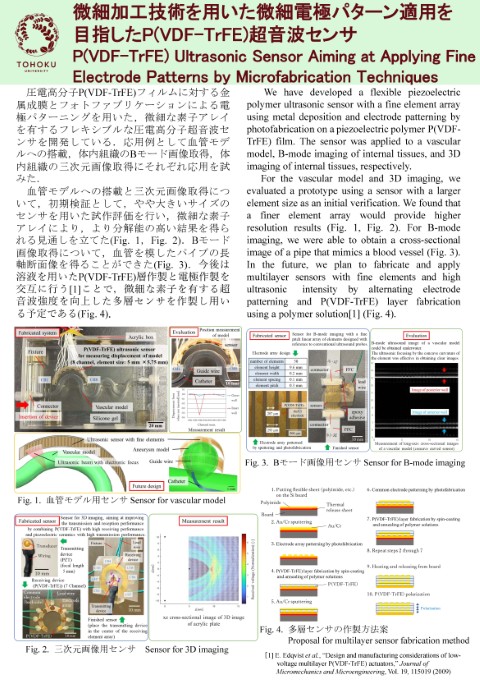

Actual surgery of human or animal experiments are used for training of doctors, evaluation of surgical techniques, and evaluation of safety or effectiveness. New organ models with microsensors have been developed for substitution of the surgery and animal experiments. By installing several microsensors in organ models which faithfully reproduce shapes and physical characteristics, quantification of effectiveness of surgery and applied force to tissues during surgical treatment.P(VDF-TrFE) Ultrasonic Sensor Aiming at Applying Fine Electrode Patterns by Microfabrication Techniques

Poster PDF of P(VDF-TrFE) Ultrasonic Sensor Aiming at Applying Fine Electrode Patterns by Microfabrication Techniques

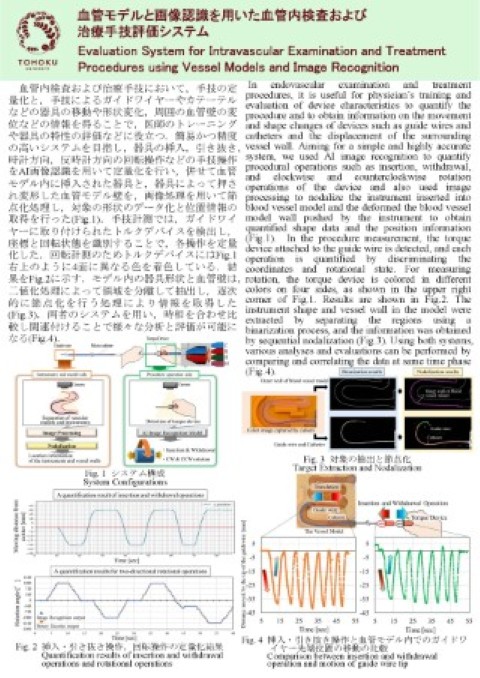

Evaluation System for Intravascular Examination and Treatment Procedures using Vessel Models and Image Recognition

Poster PDF of Evaluation System for Intravascular Examination and Treatment Procedures using Vessel Models and Image Recognition

Others

New application and possibility of the developed microfabrication technologies and assembly technologies mentioned above have been investigated by actual fabrication.

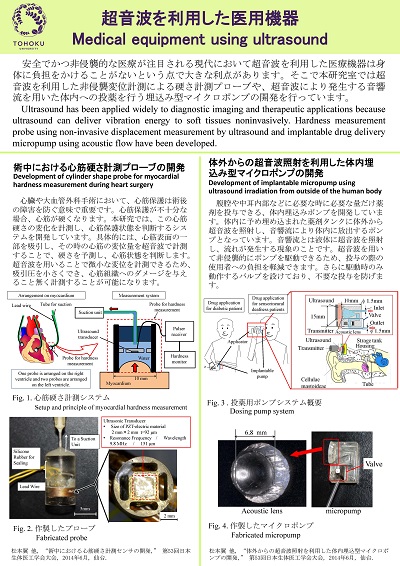

Poster PDF of medical equipments using ultrasound

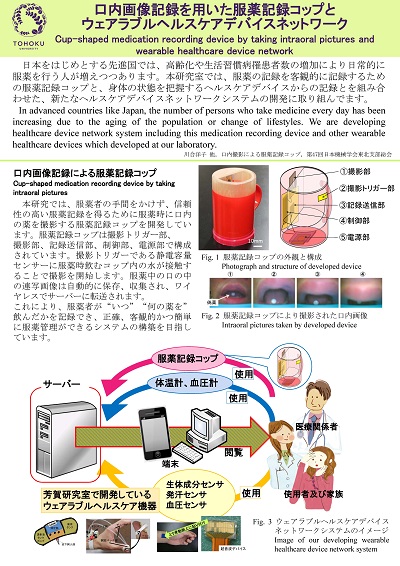

Poster PDF of cup-shaped medication device and network of wearable healthcare

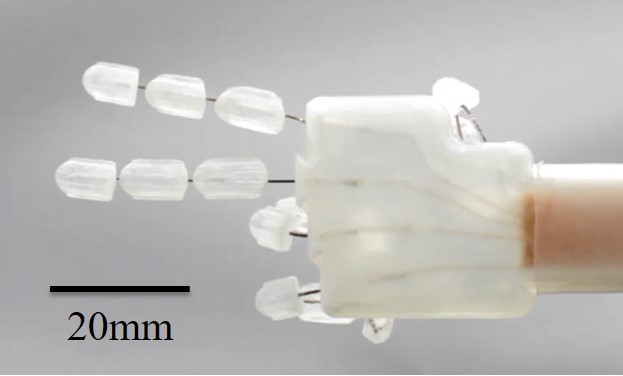

Robot hand using shape memory alloy actuated micro joints

Structure and fabrication method of bending mechanism using SMA (Shape

Memory Alloy) with good mass productivity has been developed and applied

to a robot hand.

Structure and fabrication method of bending mechanism using SMA (Shape

Memory Alloy) with good mass productivity has been developed and applied

to a robot hand.(Movie will be played by click)

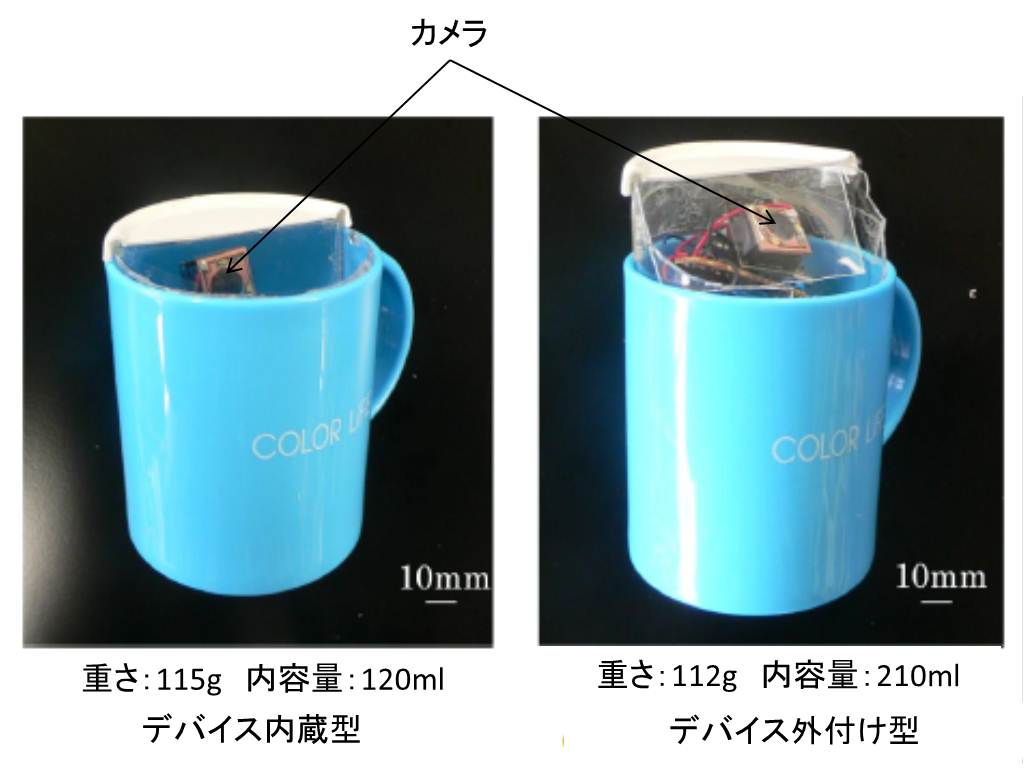

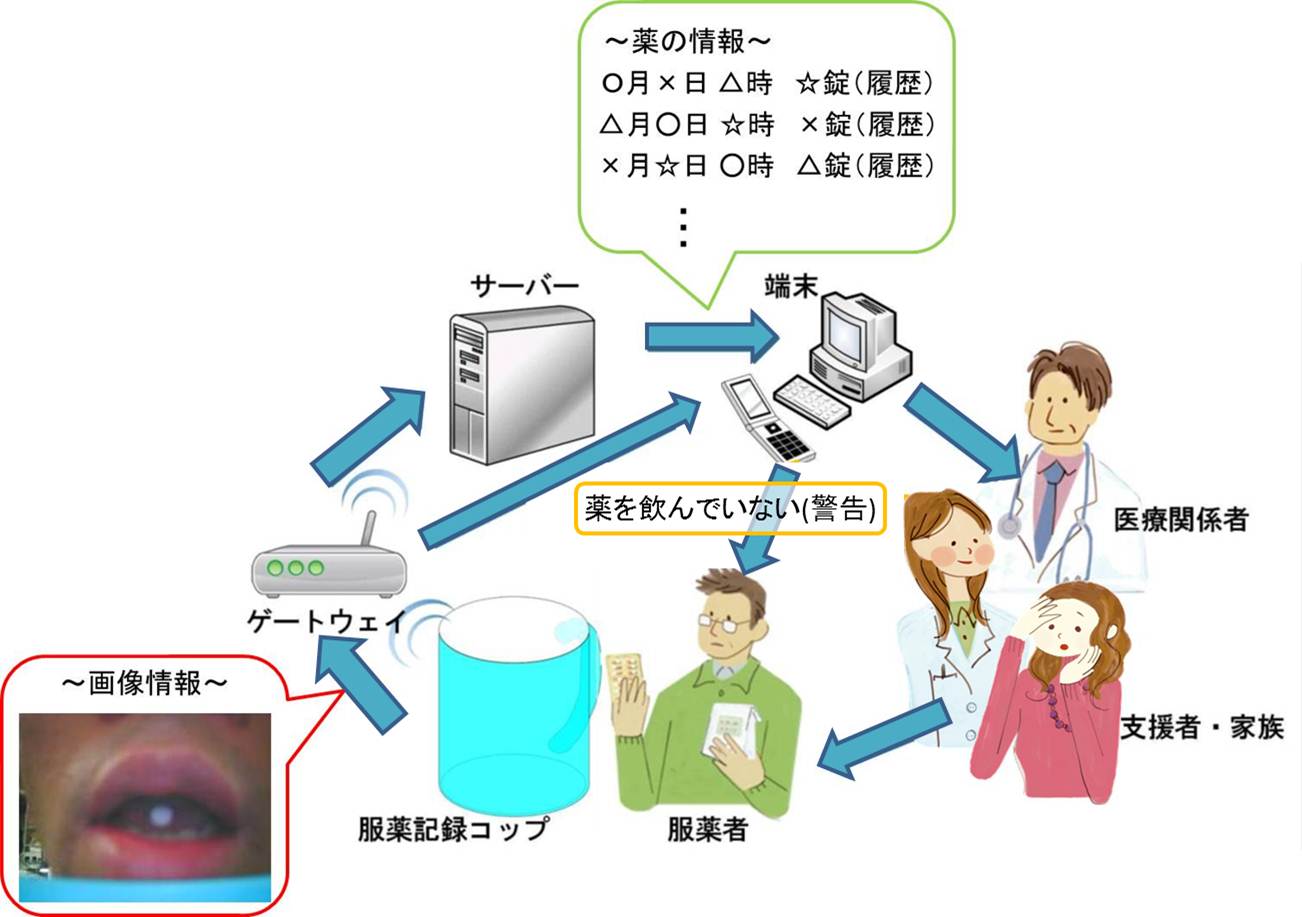

Cup-shaped Medication Recording Device

This cup-shaped device records user's medication is appropriate or not. The device has a small camera in it and records picture of pills on the tongue when user takes medicine (pills) with water using the cup. Acquired images are transmitted to a internet server wirelessly. It is expected that the device is useful for preventing mistake taking, taking failure and precise recording during clinical trial of new drugs.

This cup-shaped device records user's medication is appropriate or not. The device has a small camera in it and records picture of pills on the tongue when user takes medicine (pills) with water using the cup. Acquired images are transmitted to a internet server wirelessly. It is expected that the device is useful for preventing mistake taking, taking failure and precise recording during clinical trial of new drugs.Amusement application

Something weapon of a mobile suits has been fabricated using the active

bending mechanism using SMA (Shape Memory Alloy) actuator.

Something weapon of a mobile suits has been fabricated using the active

bending mechanism using SMA (Shape Memory Alloy) actuator.(Movie will be played by click)

Research achievements

(Under construction)

芳賀・鶴岡研究室

Haga,Tsuruoka Lab.

〒980-8579

宮城県仙台市青葉区荒巻字青葉6-6

TEL 022-795-5250

電子メール:

haga![]() bme.tohoku.ac.jp

bme.tohoku.ac.jp

(![]() は半角@に変更してください)

は半角@に変更してください)

6-6, Aza-Aoba Aramaki Aoba-ku, Sendai-shi, Miyagi-ken, 980-8579, Japan

TEL +81-22-795-5250

E-mail:haga![]() bme.tohoku.ac.jp

bme.tohoku.ac.jp